MPT by Trinity NDT- Inspection company in Bangalore, India

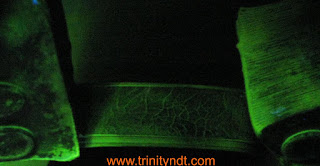

Magnetic particle testing-MPT by Fluorescent examination reveals severe grinding cracks throughout outer surface and inner surface of the tested sleeve components. It is suspected that the cracks are due to improper heat treatment and/or grinding operation/s. All the cracks are of network in nature and cannot be repaired to use the components further. Magnetic particle testing carried out with high sensitive magnetic particles with high intensity black light and latest NDT equipments. Entire lot rejected due to the defects.

To carry out the NDT tests, Trinity NDT is equipped with latest state of art NDT equipment to identify very fine cracks by using latest NDT technologies, equipments and qualified personnel with in-house NDT Training facilities to conduct the tests according to national/ international standards, Codes and client's specific requirements.

Magnetic Particle and Liquid/dye Penetrant Testing Capabilities at Trinity NDT:

* Magnetic particle testing and liquid/dye penetrant testing of raw materials,

components, and welds

* Magnetic particle testing -MPT can be performed to ASTM E709,ASTM A275, or other

client specified requirements

* Liquid/dye penetrant testing can be performed to ASTM E165 or other customer

specified requirements

* Testing performed by SNT-TC-1A qualified personnel with extensive experience

Portable testing equipment for onsite testing

* NDT Test Reports

* Custom NDT procedure development capability

Weld Inspection Capabilities:

* Certified NDT & Welding Inspectors

* Magnetic Particle and Liquid Penetrant Weld Testing

* Specialize in AWS D1.1 weld inspections

* Onsite inspection availability

* Weld Inspection Reports can be provided

To experience professional Nondestructive testing inspection services and training courses in India to level 1 level II e-mail us your testing and training requirements to: training@trinityndt.com, To know more about us please visit and enroll at www.trinityndt.com or call 'Course Director' at +91 99009 29439.

Comments

Post a Comment

Ask, Comment, Suggest to Ravi at Trinity NDT's Blog